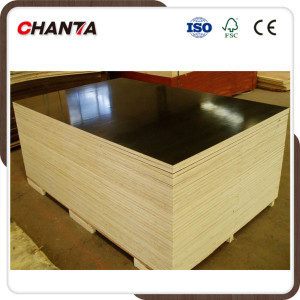

| FILM FACED PLYWOOD |

Product Name |

Film faced plywood |

F/B |

Black film, brown film,red film |

Grade |

Construntion grade(one/two time hot press) |

Core |

Poplar, hardwood, combi , and so on |

Glue |

mealmine and WBP PHENOLIC |

Thickness |

18mm |

Specification |

1220x2440mm, 1250x2500mm,915x1830mm |

Moisture Content |

8-10% |

Package |

Standard export packing |

Press |

one times press/two time press grade |

MOQ |

1x20GP |

Price Terms |

FOB, CIF, CFR |

Payment |

T/T 30%, irrevocable LC |

Delivery Time |

Within 15 days after order confirmed |

Supply Capacity |

4500 cbc/month |

Usages |

Can be widely used for building concrete, etc |

Remarks |

Top class equipment with top class produce technique; Credit first, fair trading |

Formaldehyde Emission Standards |

E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg |

| PRODUCT SHOW |

According to the repeated using time,our film faced plywood have four brands:LORDPLEX/CHANTAPLEX/ROCKAMARINE/BUILDPLEX

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they

are very light, so Chanta film faced plywood is convenient for transporting, and only one per-

son could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork co-

uld be cut into the required size.

3. Re-used: Chanta phenolic film faced plywood could be used 8-10 times.

4.Multi Using: Chanta film faced plywood could be used for wall, slab, column, beam and bri-

dge concrete pouring etc..

5. No Deformation: Chanta film faced plywood is also whole but not deformation and chipp-

ing after 72 hours cooking in boiling water.

6. High Quality Film: Chanta film faced plywood is filmed by Dynea brown or black film impor-

ted from Finland, it protect the formwork surface from the corrosion and makes the formwo-

rk durable, improves the flatness of the concrete surface and makes the concrete surface save

the second time plastering, so it could save a lot cost of construction.

| Inspection |

We have 6 QC teams to inspection such as moisture control, glue inspection both before production and after

production, material grade selection, pressing checking, and thickness checking.

Our aim is to supply high quality product with reasonable price.

| Company Infomation |

Linyi Chanta Plywood Co.,Ltd was founded in 1995 , which mainly produces film faced plywood, fancy ply-

| Packaging & Shipping |

Packing: Strong and high pallets to avoid damage by fork lift, more steel straps and thick plywood packing to

protect materials inside and avoid damage during the shipment.

Shiping: We have professional document and shipping department to provide the best service.

What is your advantage?

We have good experience in your market, we have already done 4~10 years. Same cost, we do better quality because we

have strict production processing control. We have independent inspection department for checking quality.

What is the difference between Phenolic WBP, Melamine WBP and Mr glue?

Quality is different, Phenolic WBP glue plywood can be used more than 20times, Melamine WBP glue plywood can be

used 6~10times. MR glue plywood can be used 2~4times. Phenolic WBP can bear 72 hours in boiling water, Melamine

WBP can bear around 6~ 24 hours in boiling water, and MR glue can ' t bear in boiling water.

Can you send me samples free to my office?

We would like to offer the samples free for you,but sorry that you should pay the postage , after order, we can refound

What is the moisture and thickness tolerance?

12~16%, 0.3mm for 2~7mm thickness, 0.5mm for 7~21mm thickness.

Can I get compensation if your cargo got problem?

We will undertake all of problem cause of our quality problem.

What is the difference between poplar core and hardwood core?

Poplar is soft wood, hardwood is hard wood. Hardwood core is more heavy then poplar.